Storage plan shed

Friday, November 22, 2024

How to Build a Pallet Shed with Free Plans: Simple and Affordable

Constructing a Pallet Shed Utilizing Free Plans: A Guide to Economical Construction

The allure of a cost-effective and functional storage solution is undeniable. A pallet shed, constructed using reclaimed materials and readily available free plans, offers a compelling alternative to commercially-built structures. This comprehensive guide details the process of building a robust and aesthetically pleasing pallet shed, emphasizing practicality and minimizing expenses. While utilizing free plans necessitates a degree of DIY expertise, this guide aims to simplify the process for even moderately experienced builders.

I. Planning and Preparation: Laying the Foundation for Success

Before embarking on construction, meticulous planning is paramount. This stage encompasses several key aspects that directly influence the project's outcome and longevity.

A. Sourcing Materials: The Heart of Cost-Effectiveness

The cornerstone of a budget-friendly pallet shed lies in acquiring suitable pallets at minimal or no cost. Several avenues exist:

- Local Businesses: Contact nearby supermarkets, grocery stores, and distribution centers. Many are willing to relinquish used pallets rather than dispose of them.

- Construction Sites: Construction sites often have a surplus of pallets. Inquire politely about their disposal practices and potential availability.

- Online Classifieds: Websites and applications dedicated to classified advertisements often feature free or low-cost pallet listings.

- Recycling Centers: Some recycling centers may offer pallets for a small fee or even for free.

B. Selecting a Suitable Location: Considerations for Placement

The shed's location profoundly affects its functionality and longevity. Factors to consider include:

- Accessibility: Ensure easy access for loading and unloading items.

- Ground Conditions: Level, well-drained ground is essential for a stable foundation. Consider using gravel or concrete pavers for added stability, especially in softer soils.

- Sun Exposure and Weather Protection: Position the shed to minimize direct sunlight and exposure to prevailing winds and rain. Consider the orientation in relation to potential snow accumulation.

- Local Regulations: Check local building codes and zoning regulations concerning shed construction and placement.

C. Choosing the Right Free Plans: A Foundation for Success

Numerous free pallet shed plans are available online. Thoroughly review several options to select a design matching your needs and skillset. Consider the following criteria:

- Dimensions: Choose a size appropriate for your storage requirements and the available space.

- Complexity: Opt for a plan that aligns with your construction experience. Beginners should prioritize simpler designs.

- Material List: Ensure the plan provides a detailed list of materials needed, including lumber quantity and dimensions.

- Detailed Instructions: Select plans with clear, step-by-step instructions and accompanying diagrams.

II. Construction Process: Building Your Pallet Shed

The construction process follows a logical sequence, building upon the preparatory work. Careful attention to detail is critical for a structurally sound and aesthetically pleasing result.

A. Foundation Construction: Ensuring Stability

A solid foundation is essential for a durable shed. While a simple gravel base is sufficient for lighter sheds, consider a more robust concrete slab for heavier structures or unstable ground. Ensure the base is level and adequately sized for the shed's footprint. This stage may require specialized tools and materials depending on the chosen foundation type. Refer to your chosen plan for specific requirements.

B. Pallet Preparation and Assembly: The Core Structure

Before assembling the pallets, inspect each one again for damage. Repair any significant damage using screws, wood glue, and wood filler. The assembly process typically involves connecting pallets using additional lumber and appropriate fasteners (screws, nails, or bolts). Pay close attention to the free plan's specifications for creating a structurally sound frame. Using a level ensures squareness and prevents warping. Pre-drilling holes before fastening reduces the risk of splitting the wood.

C. Roofing and Siding: Weather Protection and Aesthetics

The roofing system is crucial for protecting the shed's contents from the elements. The chosen roofing material (tar paper, corrugated metal, or recycled materials) will influence the construction method. Properly securing the roofing material is vital for preventing leaks and damage. Siding can be added for extra protection and improved aesthetics; pallet wood itself can be used for siding if creatively arranged. Consider using weather-resistant paint or sealant to enhance longevity.

D. Door and Window Installation: Access and Ventilation

Install the door and windows according to the free plan's specifications. Ensure proper sealing around the frames to prevent drafts and water infiltration. Use appropriate hinges and hardware for a secure and functional opening and closing mechanism. Consider adding latches or locks for security. Appropriate ventilation is important to prevent moisture buildup and potential damage to stored items.

III. Finishing Touches and Maintenance: Enhancing Longevity

The final stages involve refining the shed and implementing preventative maintenance to extend its lifespan.

A. Finishing and Aesthetics: Enhancing Visual Appeal

Consider adding finishing touches such as paint, stain, or sealant to protect the wood and enhance the shed's aesthetics. Select weather-resistant coatings designed for outdoor use. A fresh coat of paint can significantly improve the overall appearance and protect the wood from the elements.

B. Regular Maintenance: Ensuring Durability

Regular maintenance is crucial for prolonging the shed's life. This includes inspecting for damage, repairing any cracks or loose boards, and reapplying sealant or paint as needed. Regular cleaning prevents the buildup of dirt and debris, reducing the risk of deterioration. Inspect the foundation for settling and address any issues promptly.

C. Considerations for Advanced Features

Depending on the chosen plan and your skill level, you can incorporate advanced features like shelving, a work bench, or even electricity. However, ensure your electrical work adheres to all local codes and regulations. Proper grounding and wiring are essential for safety. Consult with a qualified electrician if you lack experience in electrical work.

Building a pallet shed using free plans provides a rewarding and cost-effective approach to creating valuable storage space. By meticulously following the planning and construction steps detailed above, you can construct a durable and aesthetically pleasing structure that meets your needs for years to come. Remember that safety should always be a priority; wear appropriate protective gear and follow safe working practices throughout the entire construction process.

Thursday, November 21, 2024

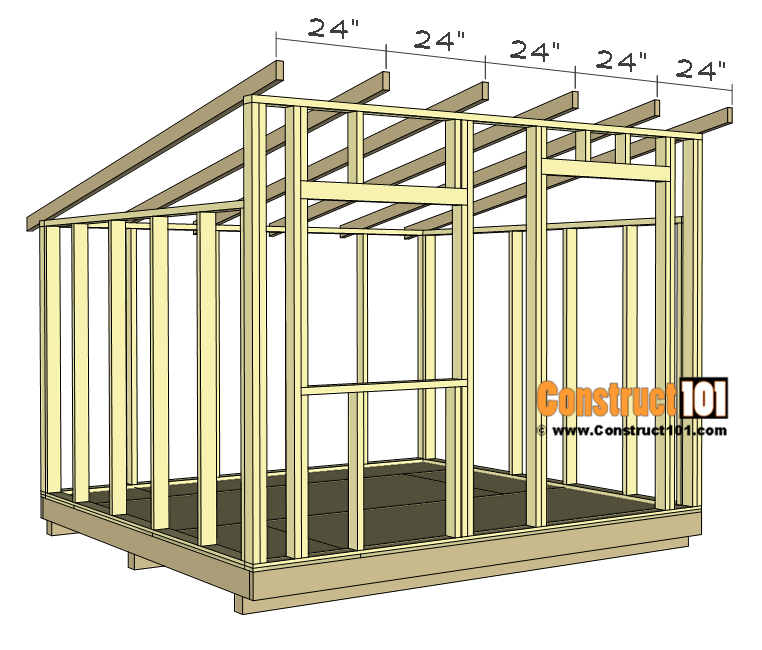

DIY Lean-To Shed: Affordable and Functional Backyard Shed Plans

DIY Lean-To Shed: Affordable and Functional Backyard Shed Plans

Tired of clutter piling up in your garage or overflowing from your basement? Yearning for extra storage space without breaking the bank? A lean-to shed might be the perfect solution! This versatile structure, attached to an existing wall (like your house or garage), offers surprisingly generous storage space at a fraction of the cost of a freestanding shed. This guide provides comprehensive, easy-to-follow plans for building your own affordable and functional lean-to shed, transforming your backyard clutter into organized calm.

Planning Your Lean-To Shed

Before you even grab a hammer, careful planning is key. Determine the size and location of your future shed. Consider the available wall space, local building codes (check with your city or county), and the overall aesthetic of your property. A smaller lean-to might suffice for storing gardening tools and seasonal decorations, while a larger one can handle bicycles, outdoor furniture, or even a small workshop. Think about access â€" will you need a door large enough to accommodate bulky items? Sketch a detailed plan, noting dimensions, materials, and placement of doors and windows. This initial step saves time and avoids costly mistakes down the line.

Essential Considerations:

- Size and Dimensions: Carefully measure your available wall space and plan accordingly.

- Building Codes: Check local regulations concerning shed construction, permits, and setbacks.

- Materials: Choose affordable yet durable materials like pressure-treated lumber for the frame and a weather-resistant roofing material.

- Access: Plan for easy access with appropriately sized doors and a convenient path.

Gathering Materials and Tools

Building a lean-to shed requires a mix of common building materials and tools. A detailed list will vary based on your specific design, but here's a general overview: Pressure-treated lumber forms the sturdy foundation. Opt for various sizes depending on the framework's needs. You'll also need roofing materials, like asphalt shingles or metal sheeting, ensuring weather resistance. Fasteners such as screws and nails are essential for securing everything together. For the floor, consider using plywood or concrete. Finally, gather your tools: a measuring tape, saw (circular saw or hand saw), drill, level, hammer, and safety glasses are crucial for a safe and efficient building process. Remember to always prioritize safety by wearing appropriate protective gear.

Construction Steps: Building Your Lean-To Shed

With your plans and materials ready, it's time to build! Start by constructing the frame, using your pressure-treated lumber. Begin by securing the base plates to the existing wall, ensuring a level foundation. Then, erect the supporting posts and attach the roof rafters. Creating a strong and level frame is paramount for stability. Once the frame is complete, attach your chosen roofing material, following manufacturer instructions. Lastly, install the siding (if desired), adding a layer of protection and enhancing the shed’s aesthetic appeal. Remember to meticulously check your work at each stage, ensuring everything is square and level.

Finishing Touches and Maintenance

Once your lean-to shed stands proudly in your backyard, add the finishing touches. A door, whether pre-hung or custom-built, provides security and access. Consider adding windows for ventilation and light. Apply a sealant or weatherproof paint to protect the wood from the elements, prolonging its lifespan. Regular maintenance is key: check for any loose screws or damaged parts and address them promptly. This proactive approach guarantees your lean-to shed will serve you faithfully for years to come, offering convenient and affordable extra storage.

DIY Pallet Shed: How to Build a Sturdy Shed with Pallets

DIY Pallet Shed: How to Build a Sturdy Shed with Pallets

Hey there, fellow DIY enthusiasts! So you're thinking about building a shed, huh? And you're eyeing those free pallets stacked up everywhere? Great idea! Building a shed from pallets can be a fantastically budget-friendly project, and it's surprisingly rewarding. This guide will walk you through the process, from planning to the final touches. Let's get started!

1. Planning Your Pallet Shed: Dreams and Reality

Before you dive headfirst into hammering and sawing, let's talk about planning. This is the crucial step where you avoid costly mistakes down the line. Think of it as laying the foundation (pun intended!) for your amazing pallet shed.

1.1 Size and Location:

First things first: how big do you want your shed to be? Consider what you'll store inside. A small shed for gardening tools is different from a larger one for bikes and lawnmowers. Also, where will it be located? Check local building codes and ensure you have enough space, access to utilities (if needed), and consider sun exposure and drainage.

1.2 Pallet Selection:

Not all pallets are created equal! You'll need to gather a significant number, and the quality matters. Look for sturdy pallets made of strong, untreated wood. Avoid pallets marked with a "HT" stamp (heat treated) which can be harder to work with. Inspect each pallet carefully for rot, damage, or loose boards. Don’t be afraid to be picky! The sturdier your starting material, the stronger your shed will be.

1.3 Design and Sketch:

Even a simple shed needs a plan. A quick sketch will help you visualize the structure and calculate the number of pallets you'll need. Think about the door placement, window placement (if any), and the overall layout. You can find tons of inspiration online â€" search for "pallet shed plans" on Pinterest or Google Images. Don't be afraid to modify existing plans to fit your needs and available pallets.

2. Gathering Your Tools and Materials

With your plan in hand, it's time to gather the necessary tools and materials. Besides the pallets themselves, you’ll need a few essentials:

- Measuring tape: Accurate measurements are key.

- Hammer: A good claw hammer is indispensable.

- Screws & Drill: Screws are much stronger than nails for this kind of project. A cordless drill makes things significantly easier.

- Circular saw or reciprocating saw: For cutting pallets to size, a circular saw is ideal, but a reciprocating saw will do the job.

- Safety Glasses and Gloves: Always prioritize safety!

- Level: To make sure your shed is... well, level.

- Post hole digger or shovel: If you’re creating a foundation.

- Wood sealant or paint (optional): To protect your shed from the elements and give it a nicer look.

- Concrete mix or gravel (optional): For a more permanent foundation.

Remember to check your local hardware store for any additional tools or materials that might be necessary based on your specific design.

3. Construction: Building Your Pallet Shed

Now for the fun part! Remember, safety first. Wear your safety glasses and gloves at all times. Let's break down the construction into manageable steps:

3.1 Foundation:

You have several options for your foundation. A simple gravel base is sufficient for a small shed, especially if it's not going to be heavily loaded. For added stability and protection from moisture, you could construct a small concrete slab. Consider your soil type and local climate when making this decision.

3.2 Frame Assembly:

Carefully dismantle some of your pallets to obtain usable boards. Start by building the frame of your shed, using these reclaimed boards and screws. Make sure the frame is square and level at each stage. This will provide the solid base for the pallet walls.

3.3 Wall Construction:

Attach the pallets to your frame. You may need to cut and adjust some pallets to fit perfectly. Ensure that you secure the pallets firmly using screws. Consider staggering the pallets slightly to add extra strength and a more visually appealing result.

3.4 Roof Construction:

Constructing the roof is similar to the walls. You can use whole pallets or cut boards, depending on your roof design. Make sure the roof has sufficient slope to allow for water drainage. Consider using a waterproof membrane or roofing felt for additional weather protection.

3.5 Door and Window Installation (if applicable):

If you're incorporating a door or windows, plan their placement carefully during the framing stage. You might need to cut openings in the pallets, ensuring the structural integrity of the shed isn't compromised. Hang the door securely and install window frames with weather-resistant sealant.

4. Finishing Touches

Once the basic structure is complete, it's time to add the finishing touches:

- Seal and Paint: Apply a wood sealant or paint to protect your shed from the elements and enhance its appearance. This will also help to prolong its lifespan.

- Flooring (Optional): Add a simple floor using plywood or reclaimed wood. This will keep your belongings dry and clean.

- Shelving (Optional): Add shelves to maximize storage space. You can construct these from more reclaimed pallet wood.

- Hardware: Install any necessary hardware such as hinges, handles, and locks.

Commonly Asked Questions

Q: How long does it take to build a pallet shed?

A: This varies greatly depending on the size and complexity of your shed, and your experience level. A small simple shed might take a weekend, while a larger, more complex project could take several weekends or even longer.

Q: Are pallet sheds durable?

A: With careful planning and construction, a pallet shed can be surprisingly durable. Using sturdy pallets and proper construction techniques ensures a strong and long-lasting structure. However, it will likely need more maintenance than a professionally built shed.

Q: Are there any permits required?

A: Building codes vary by location. Check with your local authorities to determine if permits are needed for your project. Size and location will often determine this.

Q: Can I use treated pallets?

A: While possible, using treated pallets can be problematic. Some treated lumber contains chemicals that could be harmful, especially if the shed will store food or items that come into contact with the skin. Unless you are absolutely certain of the type and safety of the treatment, it's best to avoid them.

Q: What about pest control?

A: Pallets can sometimes harbor insects or pests. Thoroughly inspect your pallets before use and consider treating them with a wood preservative before assembly to prevent any future issues.

There you have it! Building a pallet shed is a rewarding project that allows you to create something useful and unique. Remember to prioritize safety, plan carefully, and have fun with the process. Happy building!

How to Build a DIY Pallet Shed for Your Garden and Yard Equipment

Build Your Dream Pallet Shed: A DIY Guide for Garden Storage

Tired of tangled garden hoses and overflowing toolboxes cluttering your yard? Dreaming of a neat, organized space to store your outdoor equipment? Building a DIY pallet shed is a surprisingly achievable project that offers a stylish and practical solution. This guide will walk you through each step, transforming reclaimed pallets into a functional and attractive addition to your garden. Get ready to unleash your inner builder!

Planning Your Pallet Shed

Before you even touch a hammer, meticulous planning is crucial. Consider the size you need based on the equipment you plan to store. Sketch a design, noting the dimensions and the placement of doors and windows (if desired). Accurate measurements are paramount for a successful build. Next, gather your materials. Source sturdy, heat-treated pallets â€" check for any signs of rot or damage. You’ll also need screws, a drill, a saw (circular saw recommended for speed and accuracy), measuring tape, a level, and possibly a post hole digger if you plan on a permanent installation. Consider adding extra features like a roof overhang for added weather protection.

Choosing the Right Pallets

Not all pallets are created equal. Prioritize pallets marked with the HT stamp, indicating heat treatment and ensuring they're safe for use. Avoid chemically treated pallets as they may release harmful substances. Inspect each pallet carefully for rot, damage, or loose boards before incorporating them into your structure. The sturdier the pallets, the more robust your shed will be.

Constructing the Frame

With your plan and materials assembled, it’s time to build the frame. Start by laying out the base using your chosen pallets, ensuring they're level and square. Secure them together using screws, driving them at an angle for increased strength. Once the base is secure, construct the walls, using additional pallets to create the desired height. Remember to maintain a consistent spacing between the pallets to ensure structural integrity. Use the level frequently to keep everything perfectly aligned.

Securing the Walls and Roof

Attach the walls to the base frame using long screws, reinforcing the corners with extra support. For the roof, you can use additional pallets or consider a more traditional roofing material like plywood or corrugated metal sheeting for added weather protection. If using pallets for the roof, consider overlapping them to ensure water runoff. Secure the roof structure firmly to the walls.

Adding Finishing Touches

Once the basic structure is complete, you can personalize your shed. Consider adding a door using reclaimed pallet wood or purchasing a pre-made door. Install hinges and a latch for security. You might also add windows for ventilation and light. Sand any rough edges to prevent splinters. A coat of weather-resistant sealant or paint will protect your shed from the elements and enhance its aesthetic appeal.

Personalization Ideas

Let your creativity shine! Consider these additions:

- Adding shelves for organized storage.

- Painting the shed a vibrant color to complement your garden.

- Installing a simple locking mechanism for added security.

- Adding a small window for extra light and ventilation.

Enjoy Your New Pallet Shed!

Congratulations! You’ve successfully built your own DIY pallet shed. Enjoy the satisfaction of a job well done and the added organization and charm it brings to your outdoor space. Remember to regularly inspect your shed for any signs of wear and tear, and perform necessary maintenance as needed to ensure its longevity.

Budget-Friendly 10x12 Pallet Shed Plans for Creative Builders

Budget-Friendly 10x12 Pallet Shed Plans for Creative Builders

Constructing a shed can be a significant investment, but resourceful builders can achieve substantial savings by utilizing readily available and inexpensive materials such as reclaimed pallets. This comprehensive guide details the design and construction of a budget-friendly 10x12 pallet shed, emphasizing creative solutions and cost-effective strategies for the discerning DIY enthusiast.

I. Planning and Design Considerations

Before embarking on the construction, meticulous planning is paramount. This stage encompasses site selection, design refinement, material acquisition, and tool preparation. Careful consideration at this preliminary stage ensures a smoother, more efficient, and ultimately more successful build.

A. Site Selection and Preparation

The chosen site must be level and adequately sized to accommodate the 10x12 ft footprint of the shed, plus sufficient space for construction and maneuverability. Consider factors such as proximity to power sources (if electrical components are planned), drainage, and sunlight exposure. Proper site preparation involves leveling the ground, removing vegetation, and potentially compacting the soil to provide a stable foundation. A well-prepared site significantly reduces construction challenges and ensures the shed's longevity.

B. Design Refinements and Customization

While this guide provides a foundational design, adjustments can be made based on individual needs and preferences. For instance, the inclusion of windows can enhance natural light and ventilation. Consider the desired level of insulation, which directly impacts cost and energy efficiency. The inclusion of a door, shelving, or workbenches will require careful planning to integrate these elements seamlessly into the overall design. Detailed sketches and diagrams are crucial for visualizing the final product and coordinating the construction process.

C. Material Acquisition and Cost Optimization

Pallet sourcing is a key aspect of cost reduction. Locate free or low-cost pallets from local businesses, construction sites, or online classifieds. Inspect each pallet carefully for structural integrity; damaged or rotted pallets should be avoided. Supplementing pallets with inexpensive lumber for framing, roofing, and trim can be necessary. Explore options for discounted or reclaimed lumber from salvage yards or lumber mills. Hardware procurement should be approached strategically; buying in bulk often results in cost savings. A detailed materials list is essential for accurate budgeting and efficient purchasing.

D. Essential Tools and Equipment

Before commencing, ensure you possess the necessary tools. These include, but are not limited to: a hammer, pry bar, saw (circular saw, hand saw, or reciprocating saw), measuring tape, level, drill, screws, nails, safety glasses, gloves, and work boots. Consider renting specialized tools, such as a post hole digger or concrete mixer, if the budget constraints do not allow for purchasing. A well-equipped workspace minimizes delays and enhances safety.

II. Foundation and Framing

A robust foundation and sturdy frame are fundamental to a structurally sound shed. The chosen foundation type should align with the ground conditions and the shed's anticipated load. The framing structure utilizes the reclaimed pallets, supplemented where necessary with additional lumber.

A. Foundation Construction

Several foundation options exist, ranging from simple gravel pads to more permanent concrete slabs. A gravel pad is the most budget-friendly solution, requiring minimal materials and labor. Level the ground and compact the soil before laying a layer of gravel, ensuring proper drainage. For increased stability, consider using concrete blocks as a base for the pallet structure. A concrete slab provides the most robust foundation but requires more time, effort, and material cost.

B. Pallet Preparation and Framing

Thoroughly inspect all pallets for structural integrity, removing any loose nails or splinters. Disassemble the pallets, separating usable planks and discarding damaged pieces. The frame can be constructed using a combination of pallet wood and new lumber. The use of pressure-treated lumber for the base frame is recommended to resist rot and insect damage. Assemble the frame using appropriate joinery techniques, ensuring squareness and stability at all stages. Accurate measurements and precise cuts are critical for a robust structure.

C. Wall Construction and Pallet Integration

Once the frame is complete, the pallet walls can be constructed. Pallet planks can be attached directly to the frame, creating a rustic aesthetic. Consider using additional framing lumber to strengthen the pallet wall structure and ensure proper alignment. Gaps between pallets can be filled with insulation or caulking to improve energy efficiency and weather resistance. Strategic placement of doors and windows should be incorporated during this phase.

III. Roofing and Finishing Touches

Roofing and finishing touches are the final stages that transform the structure into a functional and aesthetically pleasing shed. The roof design should be compatible with local weather conditions, ensuring adequate protection from rain, snow, and wind.

A. Roofing Options and Installation

Several roofing options exist, ranging from simple corrugated metal sheets to more complex shingle roofing systems. Corrugated metal is cost-effective and durable, ideal for this budget-conscious project. Ensure proper ventilation to prevent moisture buildup. The roof structure should be adequately supported to withstand anticipated loads. Securely attach the roofing material, ensuring watertight seals at all joints.

B. Finishing Touches and Customization

Once the roof is complete, add finishing touches to enhance the shed's functionality and appearance. This may involve painting or staining the exterior, adding trim for aesthetic appeal, installing a door and windows, and constructing interior shelving or workbenches. Consider adding weather stripping around doors and windows to further enhance weather resistance. The level of customization is largely dictated by budget and preferences.

IV. Safety Precautions

Safety should remain paramount throughout the construction process. Wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and work boots. Use caution when handling power tools and sharp objects. Ensure proper ventilation in enclosed spaces. Seek assistance for tasks that are beyond your skill level. A safe work environment ensures project completion without injury or incident.

By following these detailed plans and employing resourceful techniques, creative builders can construct a functional and aesthetically pleasing 10x12 pallet shed at a significantly reduced cost. Remember that careful planning, diligent execution, and attention to detail are key to a successful project.

Basic Shed Plans for Beginners: A Guide to Easy Outdoor Projects

Basic Shed Plans for Beginners: A Guide to Easy Outdoor Projects

Building your own shed is a rewarding experience, offering a sense of accomplishment and a valuable addition to your property. This guide provides beginners with straightforward plans for constructing a simple yet functional shed. We'll walk you through the process step-by-step, demystifying the seemingly daunting task and empowering you to create your own outdoor storage solution.

Planning Your Shed Project

Before you even think about grabbing a hammer, careful planning is crucial. Start by determining the size and location of your shed. Consider your storage needs â€" will you primarily store gardening tools, bicycles, or something else entirely? A larger shed provides more space but demands more materials and effort. Choosing the right location is equally important. Ensure the area is level, allows for adequate sunlight (if desired), and complies with any local building codes and regulations. Finally, sketch a basic design â€" even a simple drawing will help you visualize the project and estimate the materials required. Don't underestimate the power of visualization; it helps prevent costly mistakes down the line.

Gathering Your Materials and Tools

Once you have your plans, create a detailed materials list. This list will include lumber (pressure-treated for longevity), screws, nails, concrete for the foundation, and any other desired features like a door and window. Consider pre-cutting lumber at your local lumberyard to save time and effort. Regarding tools, you'll need the basics: a measuring tape, level, saw (circular saw is ideal but a hand saw works in a pinch), drill, screwdriver, shovel, and possibly a post-hole digger if you're opting for a more permanent foundation. Always prioritize safety and use appropriate personal protective equipment (PPE) throughout the project. Thorough preparation minimizes frustration and keeps the project moving smoothly.

Essential Materials List:

- Pressure-treated lumber (4x4 posts, 2x4 studs, 2x6 floor joists, plywood for walls and roof)

- Concrete mix

- Roofing felt or shingles

- Exterior-grade screws and nails

- Door and window (optional)

- Weather sealant

Building the Foundation

A solid foundation is paramount for a stable shed. The simplest option is a concrete slab. Begin by excavating the area according to your shed's dimensions, ensuring a level surface. Next, construct a simple formwork (wooden frame) to contain the concrete. Pour the concrete mix into the formwork, allowing it to settle and cure for several days before proceeding. Alternatively, for a quicker solution, consider using concrete blocks or patio stones for a less permanent but still sturdy base. Remember, a level foundation prevents structural issues and makes the building process significantly easier.

Constructing the Frame and Walls

With the foundation set, begin framing the shed's walls. Assemble the wall frames using 2x4 studs, ensuring they're plumb (perfectly vertical) and square. Attach the plywood sheeting to the frames, securing it firmly with screws. Repeat this process for all four walls. Consider pre-assembling the wall frames on the ground for easier handling and alignment before lifting them onto the foundation. Accurate measurements and careful assembly at this stage are key to a structurally sound shed.

Roofing and Finishing Touches

Once the walls are up, you'll construct the roof. The simplest roof design is a gable roof (triangular shape). This requires constructing roof trusses (pre-fabricated or built on-site) and attaching them to the top plates of the walls. Cover the roof with roofing felt or shingles for weather protection. Finally, install your chosen door and window (if using), adding hinges, handles, and any necessary weather stripping. A final coat of paint or sealant protects the wood from the elements, increasing the longevity of your shed.

Building a basic shed is a manageable DIY project. By following these steps and exercising patience and precision, you can create a valuable addition to your property. Remember, safety is paramount, and don't hesitate to consult additional resources or seek help if needed. Enjoy the process and the satisfaction of creating something with your own hands!

DIY Lean-To Shed: Build a Shed That’s as Practical as It Is Stylish

DIY Lean-To Shed: Build a Shed That’s as Practical as It Is Stylish

The allure of a well-crafted outdoor structure extends beyond mere functionality. A lean-to shed, with its inherent simplicity and adaptability, presents a compelling opportunity for the discerning DIY enthusiast to create a practical and aesthetically pleasing addition to their property. This comprehensive guide will detail the process of constructing a lean-to shed, emphasizing both practical construction techniques and design considerations to ensure a structure that seamlessly integrates with its surroundings while providing ample storage or workspace.

Planning and Design: Laying the Foundation for Success

Before embarking on the construction process, meticulous planning is paramount. This involves several key steps that will significantly impact the final product’s success and longevity.

Determining Location and Dimensions:

The location of your lean-to shed is crucial. Consider factors such as proximity to existing structures, access for materials and tools during construction, and sunlight exposure. The dimensions should be carefully chosen based on your intended use. Will it serve as a simple storage shed, a workshop, or a combination of both? Accurate measurements are essential for material estimations and structural integrity.

Material Selection: Balancing Aesthetics and Durability:

The choice of materials significantly impacts both the aesthetic appeal and the longevity of your lean-to. Pressure-treated lumber is a popular choice for its resistance to rot and decay, making it ideal for the frame and foundation. For roofing, consider options such as asphalt shingles, corrugated metal, or polycarbonate panels, each offering varying degrees of durability and aesthetic appeal. Consider the local climate and anticipated weather conditions when making your selection. Furthermore, explore options for siding that complement your existing structures, maintaining a cohesive architectural style.

Permitting and Codes: Navigating Local Regulations:

Before commencing construction, it’s crucial to familiarize yourself with local building codes and permitting requirements. These regulations vary widely depending on your location and the size and complexity of your project. Obtaining the necessary permits ensures compliance and avoids potential legal issues later. Contact your local building department for specific information and guidance.

Foundation and Framing: Building a Solid Structure

The foundation and framing form the backbone of your lean-to shed. A robust and well-constructed base is crucial for ensuring stability and longevity.

Foundation Construction: Options and Considerations:

The type of foundation you choose depends on several factors, including soil conditions, budget, and the overall size and weight of the shed. Simple options include a concrete slab foundation, a gravel base, or even a raised platform using pressure-treated lumber. Each method presents different levels of complexity and cost. For a lean-to shed, a gravel base or a raised platform may suffice, provided the ground is relatively level and well-drained.

Framing the Walls and Roof: Precision and Accuracy:

Precise framing is paramount for ensuring a structurally sound and aesthetically pleasing lean-to. Start by constructing the wall frames, ensuring they are plumb and square. Use appropriate bracing to maintain stability during construction. The roof framing is equally critical. A simple lean-to roof design requires a single sloped rafter system. Carefully measure and cut the rafters to ensure proper slope and overhang. Use appropriate connectors and fasteners to secure the rafters to the wall frames. Employ appropriate techniques to ensure that the roof provides adequate water run-off and protection from the elements. Precise measurements and careful construction are critical at this stage to prevent future structural issues.

Roofing and Siding: Enhancing Aesthetics and Protection

The roofing and siding are not merely functional components; they significantly impact the overall aesthetic appeal of your lean-to shed. Careful selection and installation will greatly enhance its visual impact and longevity.

Roofing Installation: Choosing the Right Materials and Techniques:

Once the roof frame is complete, you can install the chosen roofing material. Asphalt shingles are relatively inexpensive and easy to install, offering good protection from the elements. Corrugated metal roofing is more durable and long-lasting but can be more challenging to install. Polycarbonate panels offer excellent light transmission but may be more susceptible to damage. Regardless of your choice, follow the manufacturer's instructions carefully, ensuring proper overlap and sealing to prevent leaks. Pay close attention to flashing around chimneys or other protrusions to prevent water ingress.

Siding Application: Creating a Harmonious Exterior:

The siding material should complement the overall design and surrounding environment. Consider options such as horizontal or vertical shiplap, vinyl siding, or even reclaimed wood for a rustic look. Proper installation is crucial for preventing water damage and ensuring a long-lasting finish. Ensure all seams are properly sealed and that the siding is securely fastened to the frame.

Finishing Touches and Considerations

The finishing touches are where the project truly comes to life. These details will enhance both functionality and aesthetic appeal.

Doors and Windows: Optimizing Access and Ventilation:

The type and size of doors and windows depend on the intended use of the shed. A simple shed door may suffice for storage, while a larger double door might be necessary for a workshop. Windows provide natural light and ventilation, contributing to a more pleasant workspace. Ensure that doors and windows are properly sealed and weatherproofed.

Interior Finishing: Adding Functionality and Comfort:

Interior finishing can significantly enhance the functionality and comfort of your lean-to shed. Consider adding shelving for storage, workbenches for a workshop, or even insulation for year-round use. Painting the interior walls can add a final touch of style and personality.

Safety and Maintenance: Ensuring Long-Term Durability:

Regular maintenance is crucial for preserving the longevity of your lean-to shed. Inspect the structure regularly for any signs of damage or deterioration. Address any issues promptly to prevent further problems. Consider applying a protective sealant to the wood to enhance its resistance to moisture and decay. Ensure proper ventilation to prevent mold and mildew growth. Regular cleaning will keep your shed in top condition, protecting your investment for years to come. Remember to follow all safety guidelines when working with power tools and building materials.

By meticulously following these steps, you can successfully construct a DIY lean-to shed that’s both practical and stylish. Remember that careful planning, precise execution, and attention to detail will result in a structure that not only serves its intended purpose but also enhances the aesthetic appeal of your property for years to come.